The Most Durable, Fire-Rated Debris Chute on the Market

Patented. Stainless-Steel. Fire-Rated. Built to Outperform Plastic Chutes in Every Way.

Product Introduction

Built to Last—Even Under the Most Extreme Conditions

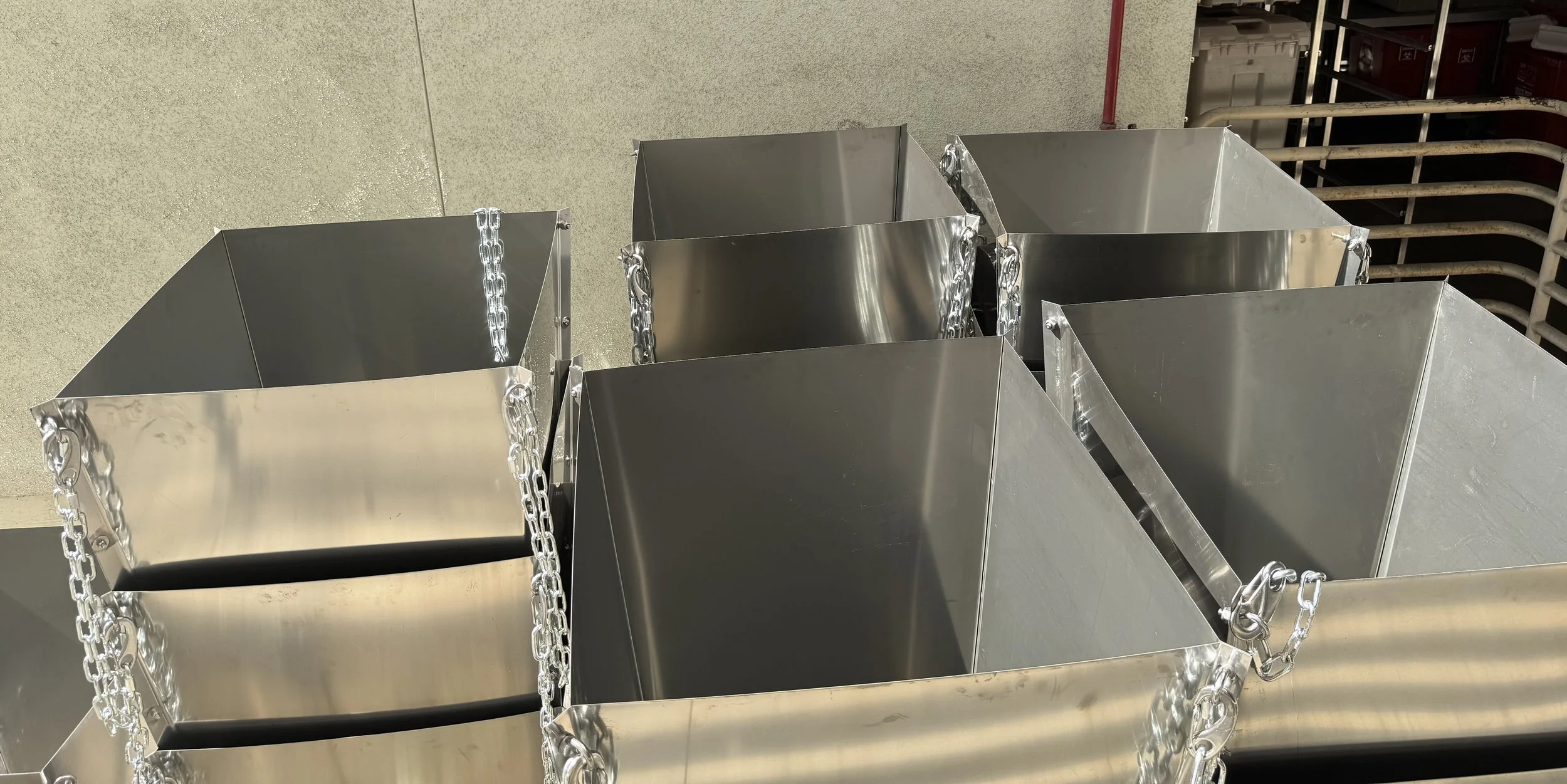

🧱 Heavy-Duty Modular

Debris Chute Panels

🔥 Fire-Rated Debris Chutes

Material: 20-Gauge 304 Stainless Steel

Certification: ASTM E84 / UL 723 Compliant

Rating: Flame Spread Index 0 | Smoke Developed Index 10 → Class A – Highest Rating Possible.

📐 Dimensions & Profile

Top Width: 27″

Bottom Width: 22″

Length: 48″ (Usable Length: 45″)

Side Profile: 45° Bent from Flat.

Connection Holes: Six (6) 5/16″ Pre-Drilled per Side.

🔗 Connection System

Vertical Linkage: Chain & Snap Hook → Allows Quick Height Adjustment & Rapid Installation.

Stacking: Fully Stackable for Easy Storage & Transport.

🔄 Hopper-Ready Conversion

Modular Adaptation: Regular sections can be converted into a hopper by replacing only 1 panel.

Parts: All components field-replaceable & independently stocked.

Hopper Section

Where the Drop Starts

🔧 Product ID: SSHS

20-Gauge 304 Stainless Steel Hopper Section with Chains

Total Length: 48″

Intake Opening: 24″ wide × 24″ tall × 18″ deep

Material Build: Reinforced stainless-steel sheet metal with integrated HPG Unistrut.

Included Safety Feature: Pre-installed protection door at intake.

Mounting: Compatible with top frame or scaffold outrigger bracket.

Shipping Weight: 76 lbs.

This is the starting point of your system—the reinforced gateway built to take the brunt of debris flow.

Regular Section

The Core Panel That Holds It All Together

Built strong. Built simple. Built to last.

🔧 Product ID: SSRS

20-Gauge 304 Stainless-Steel Section with Chains

Total Length: 48″

Usable Length: 44″

Top Opening: 27″ × 27″ → Equivalent Diameter: 34.39″

Bottom Opening: 20″ × 20″ → Equivalent Diameter: 25.48″

Diagonal (Outer Corner to Corner): 38.2″

Shipping Weight: 58 lbs.

Built strong. Built simple. Built to last. This is the heart of your chute system—modular, fire-rated, and ready for abuse.

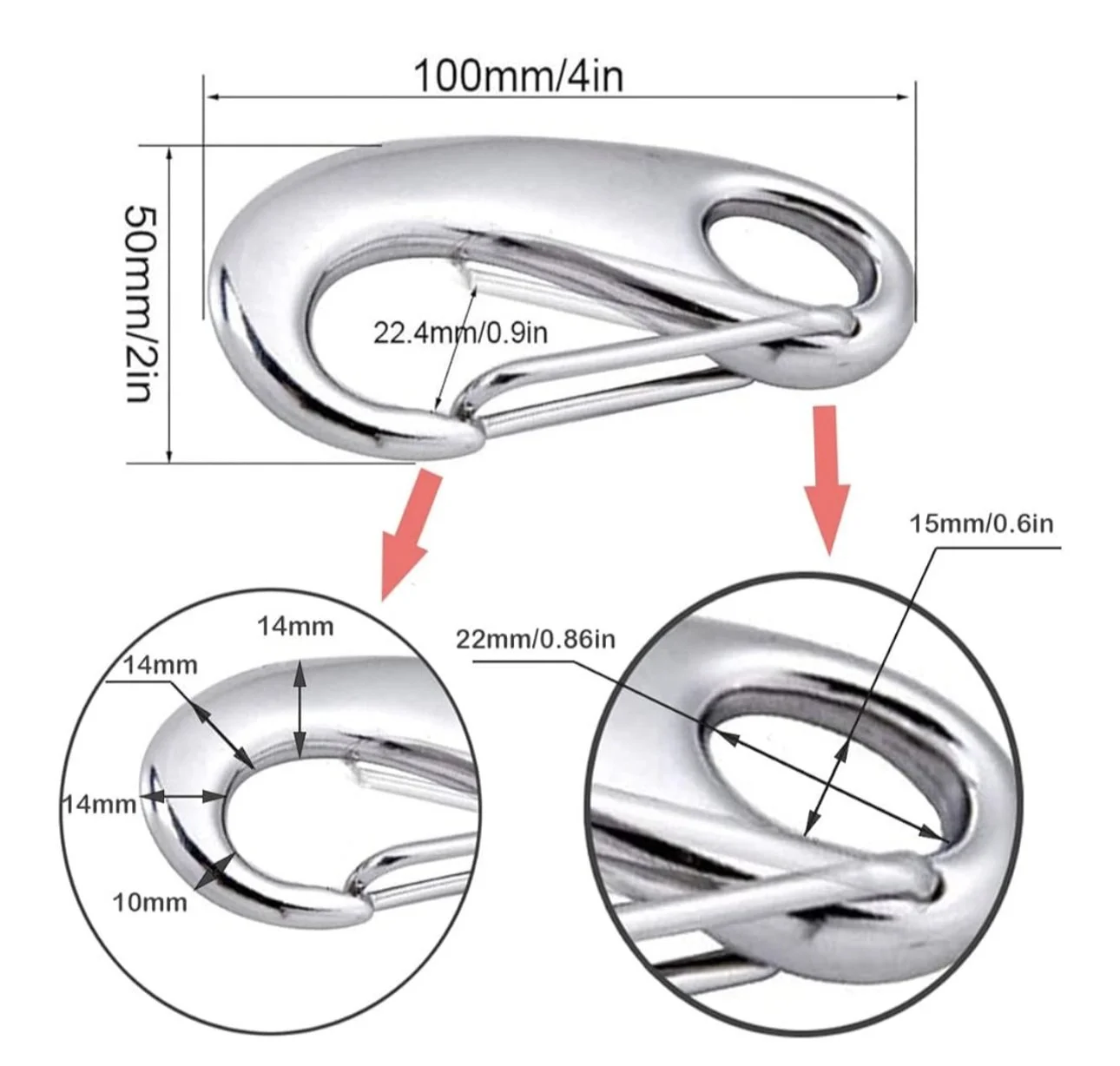

🪝 Snap Hook Pack – 316 Stainless Steel

🔧 Product ID: SSSH

4-Pack of Marine-Grade Snap Hooks for Chute System Assembly

Material: 316 Stainless Steel

Length: 4″

Working Load Limit: 1,100 lbs. (per hook)

Safety Margin: Built-in 4:1 factor

Grade: Marine-grade corrosion resistance for harsh environments.

Application: For vertical linkage between chute to chute or hoppers.

Designed for rugged jobsite use—strong, secure, and built to last under pressure.

Hardware & Accessories

From Chutes to Chains Holds Strong! Safety First!

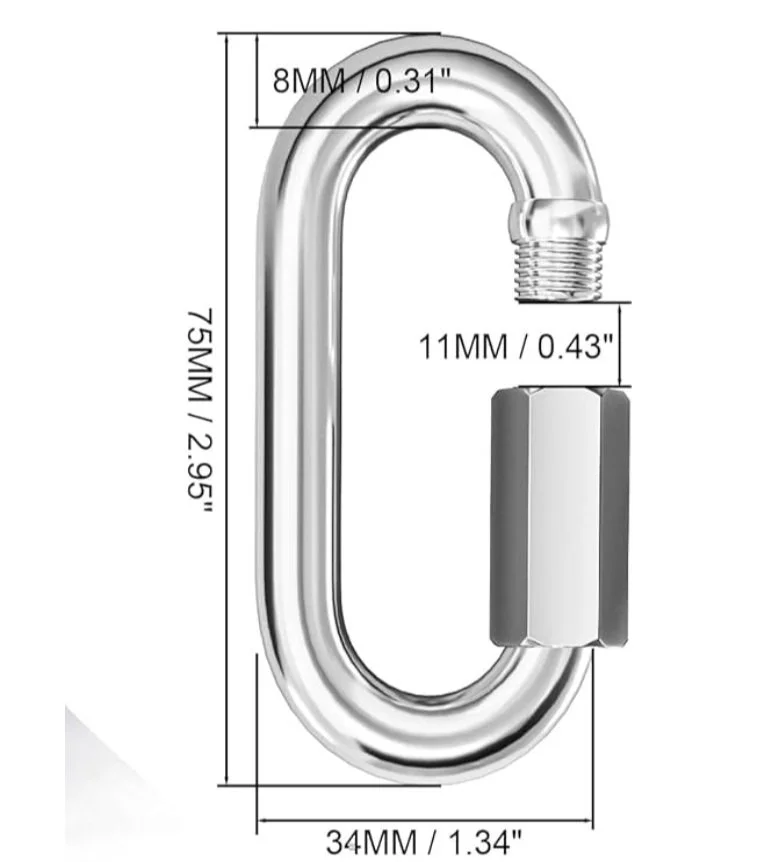

🔗 Quick Link Pack – 316 Stainless Steel (8-Pack)

🔧 Product ID: SSLC

8-Pack of Industrial-Grade Quick Links for Modular Panel Connection

Material: 316 Stainless Steel

Length: 2.95″

Diameter: 0.31″

Width: 1.34″

Working Load Limit: 1,525 lbs. per unit

Safety Margin: Built-in 4:1 factor

Use Case: Secure hooks and eye-bolts to the chain.

Tough, tested, and torqued for the trades. This hardware is spec'd to perform where cheap clips fail.

⛓️ Chain Kit – Stainless Steel

🔧 Product ID: SSC

304 Stainless Steel Chain with Snap Hook & Quick Link

Total Chain Length: 38″

Overall System Length: 45″ (Includes hook, quick links, and eye bolt)

Working Load Limit: 1,570 lbs.

Safety Factor: Built-in 4:1 factor.

Function: Used to make a complete and continues debris chute setup.

Secure. Durable. Fire-rated. This chain anchors your system—literally and legally.

🔧 Rigging Cross Spreader Bar

🔧 Product ID: RCSB

1. Purpose: Integrate a crossbar attachment that allows for balanced lifting and maneuvering of chute sections using a winch or hoist.

2. Suggested Features:

Mounting Points: Welded or bolted eyes/hooks rated for vertical lift.

Shackle: For winch line attachment with balanced weight distribution.

Finish: Powder coat to match existing units and maintain aesthetic.

3. Use Case Benefits:

Safer and faster chute placement during installation.

Reduces manual labor strain during installation.

Enables crane or winch lifting for high-rise or tight-access deployment.

Transporting Chutes

Compact Design. Big Results.

🚚 Logistics & Shipping Efficiency

Just Chutes are designed for real-world logistics — whether you have a flatbed or a pickup.

📦 Palletized for Maximum Efficiency

~ 200 panels per pallet = Up to 50 complete chute sections → Massive space savings on-site and in storage

🚛 Full Truckload Optimization

~ 2,800 panels per semi-truck = Up to 700 chute sections → Cut freight costs and reduce delivery frequency

🔧 Hopper Shipping Made Simple

Hoppers ship in 2 parts:

One side panel

One intake section with pre-installed protection door → Streamlined handling and faster setup.

✔ 70’ of Regular Chute Sections + 1 Assembled Hopper

Fits neatly in a standard pickup truck.

✔ 70’ Installed – 18 Regular Chute Sections

Modular Efficiency at its best.

✘ 50’ of Plastic Chutes = Overflowing Pickup

Awkward. Bulky. Limited transport options.

🛠️ Built for the Jobsite

Heavy-Duty 304 Stainless Steel Corrosion-resistant, fire-rated, and built to outlast plastic alternatives in harsh environments.

Modular Design Stackable, interchangeable panels allow for flexible chute lengths and easy transport.

Low Storage Footprint Panels nest efficiently, reducing storage space by over 60% compared to traditional systems.

🔥 Fire-Rated & Code Compliant

ASTM E84 / UL 723 Certified Flame Spread Index: 0 Smoke Developed Index: 10 Class A – Highest Rating Possible

Meets OSHA & Cal-OSHA Tie-Off Requirements Integrated anchor points for compliant installation and safe operation.

⚡ Fast Assembly from Pallet to Location

5 Minutes per Regular Chute Section

10 Minutes per Hopper Section

🔁 Replaceable Parts

Damaged a panel? No problem. Every component is field-replaceable to minimize downtime and maximize ROI.

🔩 Key Product Features & Benefits

🧱 Installation Guidelines – Just Chutes Fire-Rated System

🔧 1. Mounting the System

Secure the top-frame mount or outrigger scaffold support to a rigid structure using approved hardware.

Ensure all anchor points are rated for the system’s total load capacity.

🪝 2. Hopper Panel Attachment

Connect the hopper sections.

Confirm the chain is fully locked before use.

🧩 3. Stacking Chute Panels

Stack panels with bends facing upward to ensure proper nesting.

Chutes can also be stacked inside each other post assembly.

🪢 4. Tie-Back Requirements

Install tie-back cables or ropes every 30 vertical feet for added stability in windy conditions.

Anchor tie-backs to a secure structure (e.g., scaffold, parapet, window frame, or concrete anchor).

🔍 5. Pre-Use Inspection

Before each use:

✅ Check all connection points for wear, cracks, or deformation.

✅ Verify all quick-links, chains, and tie-backs are secure.

✅ Ensure chute is free of obstructions and debris.

⚠️ 6. Safety Reminders

🚷 Never stand beneath the chute during operation.

🌬️ Do not use in high-wind conditions without additional bracing.

🔥 Keep chute away from open flames or high-heat sources.

🏷️ Custom Branding

Add your company logo to each panel via high-temp laser etching or heavy-duty vinyl stamping.

Perfect for jobsite visibility, theft deterrence, and brand pride.

🔩 Reinforced Lower Panels

Swap in extra-thick stainless-steel panels for the chute’s lowest section.

Ideal where impact is highest—like angled drops into dumpsters.

Reduces denting and prolongs lifespan under heavy debris flow.

🧰 Optional Add-Ons

🛠 Installation Time-Lapse Video

Installed in just 27 minutes - from ground to 70’ high

🛠 Assembly Time-Lapse Video

Assembled from pickup truck to staging area in on clean motion

⚠️ Debris Chute System Disclaimer

🛠️ General Use

This chute system is intended for trained construction professionals only. Improper use, installation, or failure to follow safety procedures may result in serious injury, death, or major property damage.

🚫 Liability Disclaimer

The manufacturer is not responsible for injury, damage, or failure resulting from:

❌ Improper installation

❌ Unauthorized modifications

❌ Overloading or misuse

❌ Operation in unsafe conditions (e.g., high wind, unsecured units).

By using this product, the user accepts all responsibility for compliance with local safety laws, job site protocols, and safe operating practices.

🧰 Installation & Supervision

Must be installed or supervised by a qualified professional.

All installations must comply with OSHA, Cal-OSHA, ANSI, NFPA, and local building codes.

System must be securely anchored to a rigid structure using approved hardware.

✅ Daily Use Checklist

Before each use:

🔍 Inspect all panels, hoppers, and support hardware for cracks, deformation, or wear.

🔧 Verify all connections are properly locked and tightened.

🔥 Ensure fire-resistant materials are intact and not compromised.

🌬️ Avoid use during excessive wind or weather conditions.

⚠️ Safety Warnings

🚷 Never stand or allow personnel beneath the chute during operation.

🧱 Do not use damaged, cracked, or missing components—replace immediately.

🔥 Do not expose the chute to open flames or high-heat environments.

🧩 Maintenance & Parts

🛑 Use only original replacement parts supplied by Just Chutes.

🧯 Do not cut, weld, or alter any system components.

🔁 Replace damaged or worn panels promptly to maintain safety and compliance.